Residual leucocyte counter ADAM-rWBC

45 sec 3 steps accuracy=0.99

The ADAM-rWBC system automatically counts the number of residual white blood cells (rWBC) in leukoreduced products. The device ensures that the white blood cell count meets the standards used to minimise complications associated with hospital transfusions.

Features

All procedures are automated once the sample loaded blade is inserted into the device. It takes only 45 seconds to count the residual leucocytes.

Automated cell counting eliminates errors or subjective user interpretation that can be encountered when counting residual leukocytes when using other methods.

• r2= 0,989

• Substantially equivalent to flow cytometry

New technology supporting precision

The ADAM-rWBC system is an accurate, automated optical system capable of analysing fluorescent images. ADAM-rWBC2 automatically focuses on the blade. Stained cells are sampled and recorded by a sensitive CMOS camera. ADAM-rWBC2 analyzes and reports a result using integral image analysis software

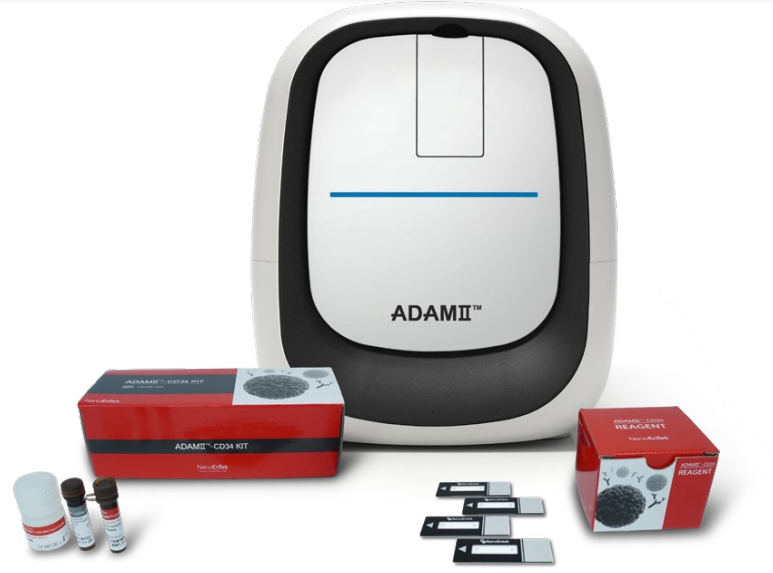

Stem cell counting system ADAM II CD34

The ADAMII™ CD34 simultaneously captures a series of bright-field and fluorescent images of the sample from the test slide and uses sophisticated digital image analysis algorithms to determine the total and fluorescent cell counts and calculate their concentrations.

• An integrated precision microscope with fluorescence optics and image analysis software

• After CD34 cells are stained with CD34 fluorescent antibody, images are automatically taken.

• Contorul CD34 are nevoie de max. 136 de imagini prin mișcarea treptei X-Y automate

A total of 18 PBSC samples were used to compare ADAMII and flow cytometry. Linear regression analysis revealed a strong correlation between the absolute CD34+ number and cell fractions (%) data obtained with ADAMII™ and those obtained using flow cytometry for PBSC (Absolute CD34 number, R2 = 0.99; CD34+ fractions (%), R2 = 0.98).

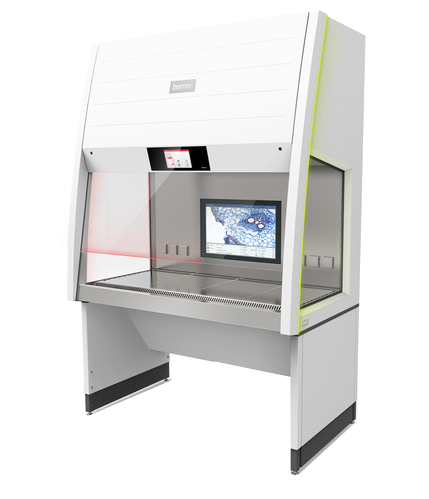

Laminar flow safety cabinet Claire Pure

Claire pure offers the best technological quality at an attractive price. The LED lighting system in the work area, the high-performance EC fans and the touch screen with intuitive menu navigation form the technical basis for the highest functionality.

This is complemented by a wide range of dedicated options for all major applications. With outstanding energy efficiency and low purchase and operating costs, Claire is the leading edge in efficiency. Filters are the most important safety features for safety cabinets. They form the most important barrier to people, environment and product.

As part of a research project, we were able to optimise the fluid mechanics aspects specific to HEPA filters within the cartridge equipped with three filter systems.

Thanks to a newly designed intake port and air ducts, we have been able to achieve improved operating performance. Noise levels have been reduced, along with energy consumption, and filter life has been optimised.

The proven properties have remained the same:

• small size and compact design

• maximum legroom in the system area with the 3 filters

• insignificant changes - 50% - and the same test results as traditional filtration systems

• possibility to modify a low contamination filter according to DIN 12980:2016

• fits into most standard waste containers or autoclaves

The new generation of safety cabinets is the result of decades of experience, innovative German engineering and the use of state-of-the-art "Made in Germany" technology.

• Very quiet and pleasant working conditions with sound levels down to 49 dB [A].

• Uniform and bright illumination of the work area thanks to high-quality LED technology with anti-glare function

• Working surface height of 770 mm. Ideal as a seated work surface according to DIN EN ISO 14738.

• High quality workspace High quality & solid construction, made entirely of stainless steel.

• Without joint areas and made in one piece. Durable and easy to clean.

• Exceptional legroom thanks to the positioning of the 3-filter system.

• Ideal for precision work: armrest and headrest at the same height. So the full height of the nozzle is available for easy movement.

High functionality is provided in particular by the wide range of options for all major applications and includes, among others:

• Various interfaces and additional power sockets

• Powerful UV-C disinfection systems

• Low-vibration measuring worktables

• Work tables for continuous operation

• Various connectors for liquid and gaseous media

• Isokinetic sampling probe for particle monitoring

• Exhaust Duct Flex for connection and operation without reverse connection of air exhaust systems

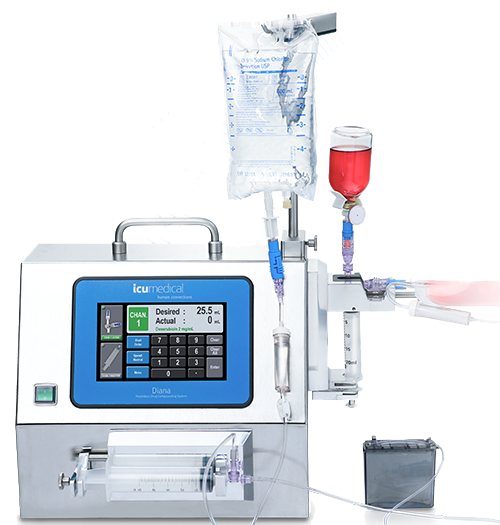

Automatic mixing system for cytostatics DIANA

A completely closed system takes contamination out of the equation

Automated hazardous substance mixing system for the safe and correct preparation of cytostatics.

The microbiologically and mechanically closed system design is achieved through a series of innovative needle-free components, including pre-packaged prep kits and many components of the closed ChemoClave or ChemoLock system for intensive care units. These devices attach to all containers dispensing or receiving a drug in the mixing process to protect the patient from exposure to environmental contaminants, while protecting the healthcare setting from both drug exposure and accidental spills.